Tube Selection and Environment Tips for Thermal Printers

Table of Contents

ToggleBasic Principles of Thermal Printers

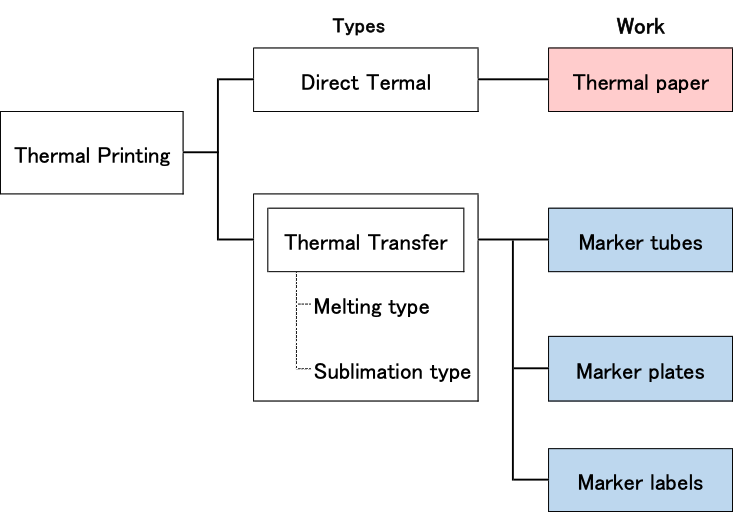

Thermal printing is a technology that uses heating elements in the printhead to print. It is widely used for applications such as labels, barcodes, and receipts. There are two types of thermal printing methods:

Direct Thermal Method

In this method, heat is directly applied to thermal paper, which reacts by producing color to create the printed image. While this method is ink-free and cost-effective, printed materials are prone to degradation over time.

Thermal Transfer Method

This method transfers ink by heating a ribbon. It is suitable for durable, high-quality printing with greater color flexibility, making it ideal for labels used outdoors or for extended periods. Although it requires ink ribbons as consumables, it is characterized by excellent weather resistance.

Selection Criteria for Suitable Tubing

The choice of tubing used with thermal printers significantly impacts print quality and printer longevity. Tube hardness is particularly important, as tubes that are too hard or too soft can cause issues. The following outlines the effects of tube hardness:

Effects of Tube Hardness

Tube hardness can impact both print quality and the lifespan of the printer and its components.

When Tubes Are Too Hard

- Damage to the Thermal Head: Tubes that are too hard place excessive stress on the thermal head, potentially causing missing dots and reduced print quality.

- Printing Quality Decline Due to Meandering: Hard tubes are prone to twisting and can meander inside the printer, leading to incomplete print characters. This tends to be more common with non-genuine tubes compared to our genuine CTK tubes, which offer better print quality.

When Tubes Are Too Soft

- Reduced Tube Stability: Soft tubes are prone to stretching, which can lead to unstable tube cutting lengths and print position, ultimately impacting print quality.

- Ink Transfer and Roller Contamination Issues: Soft tubes can cause ink transfer to non-heated areas, potentially contaminating rollers, which may then retransfer ink onto printed materials. Contact with the guide rollers may also cause tube's deformation (such as wrinkles), leading to print defects.

Impact of Printing Environment Temperature

Printing in Warm Environments

Printing in high-temperature environments can cause tubes to stretch excessively and result in unstable ink transfer. Extra attention is required for tubing selection and maintenance in warm conditions.

Printing in Cold Environments

In cold environments, softer tubes become firmer, which can make printing easier. Additionally, tube cutters may have an extended lifespan when operating in cooler conditions.

Conclusion

There is a past example where using genuine CTK tubes quickly resolved print fading issues. In addition to addressing the print quality concerns outlined above, please use our genuine tubes, which have been verified for durability in printed materials.

Hotmarker, Next Level Thermal Transfer Printing Solution

CTK offers three models of mark tube printers that serve wiring identification purposes.

In addition, the latter is equipped with the function to cut a mark tube into pieces and then align and paste them onto a tape.

The offering to the overseas market is the SP8600, which is compatible with CE markings.

For more information, please refer to this brochure.