Custom Heat Shrink Tubings Printing: 4 Methods Explained

Are you looking for a method of heat shrink printing that can meet your specific needs? Well, Hotmarker could be perfect for you. Heat Shrink Printing has been successfully used in the industries of wire identification, labeling and medical products with great success.

With superior adhesion capabilities at temperatures ranging from 150 to 360°F – higher than any other type of shrink film/tubings– this printing process can easily accommodate complex shapes and is suited to many different materials, which makes it an attractive choice for large-scale production runs.

In this blog post, we will discuss the benefits of Hotmarker Heat Shrink Printing and explain how it works so that you can make an informed decision when deciding on the best way to fulfill your needs!

Table of Contents

ToggleMethods of Heat Shrink Printing

Thermal Transfer Printing

Thermal printing is a versatile and efficient printing method that has revolutionized the way we create product labels, bar codes, and receipts. At the heart of this printing process is a heating element, which is located at the tip of a thermal printhead.

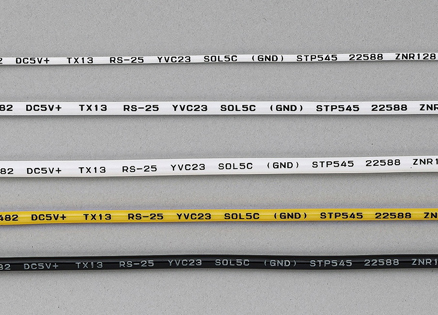

Custom Heat Shrink Tubings (Printed by Hotmarker SP8600)

Process of Thermal Transfer Printing

The process involves the transfer of ink from a marking foil to an object through the application of heat.

1. The first step involves selecting the right object and marking foill for the intended application and setting up the printer.

2. The next step includes designing the image or text to be printed and transferring it onto special software for the printer.

3. The printer prints the image or text onto the marking foil, which is then transferred to the object using heat and pressure.

The resulting print is sharp, bright, and long-lasting, making thermal transfer printing an ideal method for printing barcodes, product labels, and other materials that require durability. While the process may seem complex, following each step carefully ensures a successful outcome and high-quality prints.

Advantages

Thermal transfer printing may not be the most commonly known printing method, but it definitely has its advantages, especially when it comes to printing on heat-shrink tubings. Unlike other printing methods, thermal transfer printing can print on a variety of surfaces, including plastics and fabrics.

Additionally, this method produces crisp, accurate prints even on the smallest fonts and images. When it comes to printing heat shrink tubings, thermal transfer printing is the best option as it can withstand harsh environments without fading or smudging, making it perfect for applications in aerospace and telecommunications industries.

Limitations

While this printing method may work well for wide variety of applications, hot stamping may be a better alternative when the object is bulky or has uneven surface. Hot stamping is also suitable for tubings that come with adhesive.

It is important to be aware of its limitations and consider alternative methods before making a final decision.

Hot Stamping

Hot stamping printers offer a unique and efficient way to create prints on various materials by using a type piece and pigment. By pressing the type onto the material, engravings are formed while the pigment adheres to the surface. This process is conducted by an air cylinder or similar mechanism.

It is perfect for printing on plastic molded products, control cables, and coated electric wires like bundling bands and connectors. What sets hot stamping printers apart is their ability to easily change print colors.

Additionally, no drying time is required since no liquid ink or organic solvents are used in the printing process. With hot stamping printers, businesses can produce high-quality prints quickly and easily.

CTK's Hot Stamping Machine, The latest model, B330P (Coming Soon)

Process of Hot Stamping

Hot stamping is a fascinating and intricate process that requires skill, precision, and patience.

1. It all starts with setting up the equipment, making sure the temperatures are just right and the stamping types are positioned correctly.

2. Once everything is in place, it's time for the printing stage. This is where the magic happens – the foil is heated up and then pressed onto the product, leaving behind a beautiful, shiny design.

3. Finally, the completion stage involves inspecting the finished product and making any necessary adjustments or touch-ups.

It's a meticulous process, but the result is a product that is both durable and eye-catching.

Advantages

Compared to other printing methods, hot stamping is not only faster and more efficient, but it also offers more flexibility in terms of design and color options. Moreover, heat shrink tubings printed with hot stamping have a smoother finish and a more professional look, making them ideal for a wide range of applications, from automotive and aerospace to industrial and medical use.

Limitations

Hot stamping creates markings through direct contact, which necessitates pauses between each marking. Plus, when there's a need to change the print text, the types have to be physically rearranged.

Laser Printing

Harnessing the precision of focused light beams, laser printing offers a distinct advantage due to its non-contact nature, removing the need for intervals between markings, a trait commonly associated with hot stamping. Nonetheless, it comes with drawbacks: the method is often restricted to mono-color, there are potential environmental concerns arising from emissions, and initial setup costs can be substantial.

Inkjet Marking

Using droplets of ink projected from a nozzle, inkjet marking also provides the benefit of a non-contact printing process and doesn't require pauses between markings. But it's not without its challenges: if the print erodes, it becomes unreadable, unlike the lasting indents left by hot stamping. There are environmental implications due to emissions, and the system usually demands higher maintenance costs.

Hotmarker: A Reliable Solution for Custom Printed Cable Ties

To sum up, Hotmarker provides a reliable and hassle-free printing solution for heat-shrink material. Its versatile design allows it to be used for different types of materials in a variety of shapes and compositions. With its durable construction and professional engineering, the Hotmarker (both Thermal Transfer/Hot Stamping models) is capable of producing high-quality and reliable prints every time.

Furthermore, its user-friendly interface makes it easy to handle and ensures that the entire printing process can be done quickly and efficiently. It’s definitely an excellent option for businesses that wish to add a touch of professionalism to their printed materials while still keeping cost low.