Hot (Foil) Stamping/Printing: Guide for Professionals

What is Hot (Foil) Stamping/Printing?

Hot (Foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and pigment onto it. This pressed type deforms the material and causes engravings, while the pigment adheres to the material due to heat. The pressing process is conducted by either an air cylinder or a similar mechanism.

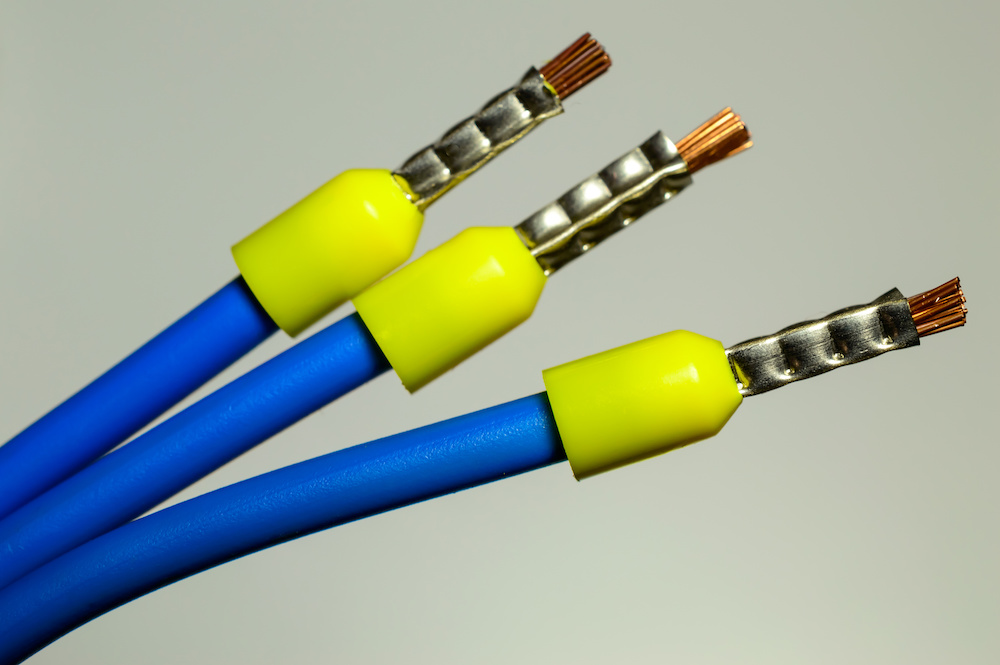

The printable materials include plastic molded products, such as bundling bands and connectors, control cables, and coated electric wires.

Furthermore, changing the print color in such a printer can be easily accomplished by replacing the marking foil. Moreover, no drying time is required, since liquid ink or organic solvents are not used in this process.

How does hot (foil) stamping work?

Hot (foil) stamping printers function according to the following 3-step process.

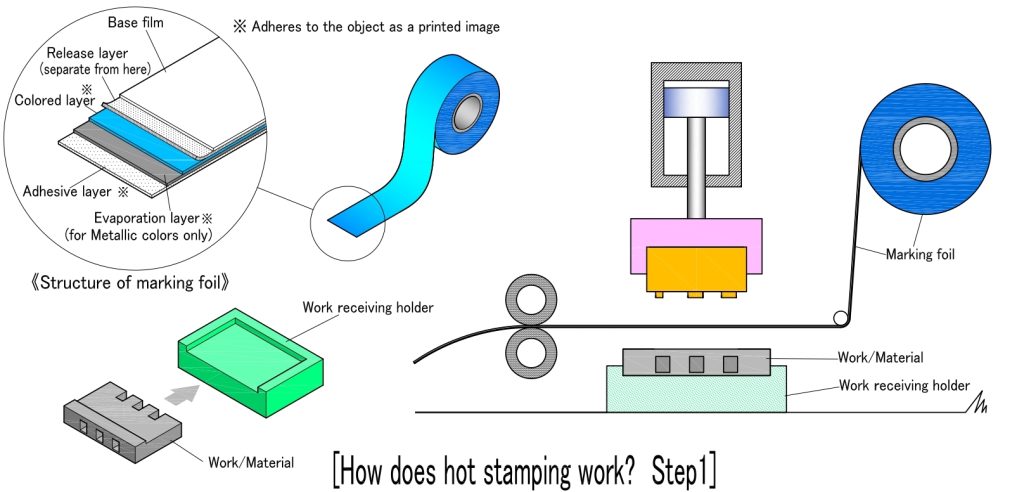

【Step1】 Setting

This step involves setting the material on the work receiving holder.

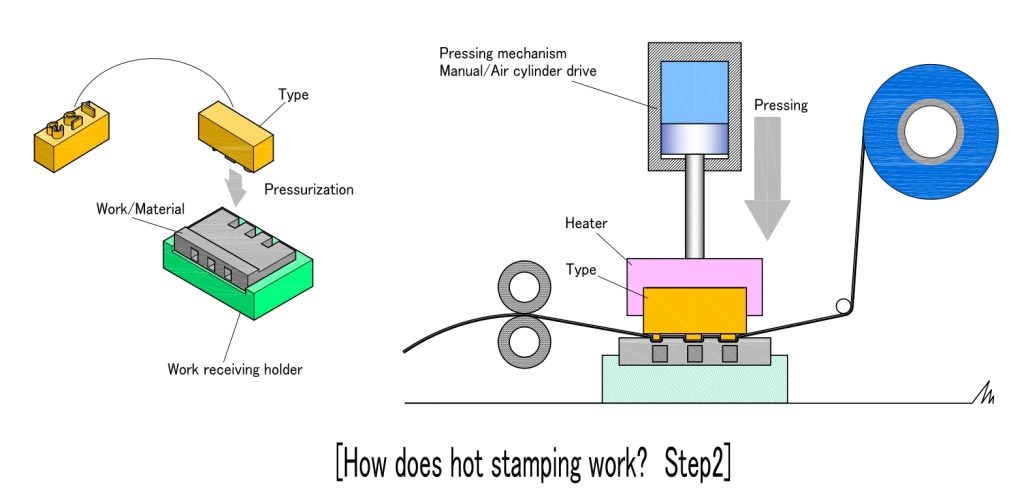

【Step2】Printing

In the next step, the device is switched on and the desired type temperature is set on the temperature controller.

Once the temperature of the type increases to reach the set value, the type is pressed onto the material either manually or by the descending force of an air cylinder. The pigment of the marking foil that touches the protruding part of the type comes in contact with the material.

Subsequently, the pigment is separated from the release layer of the marking foil and transferred to the material by heat and pressure, which simultaneously adds color to the print.

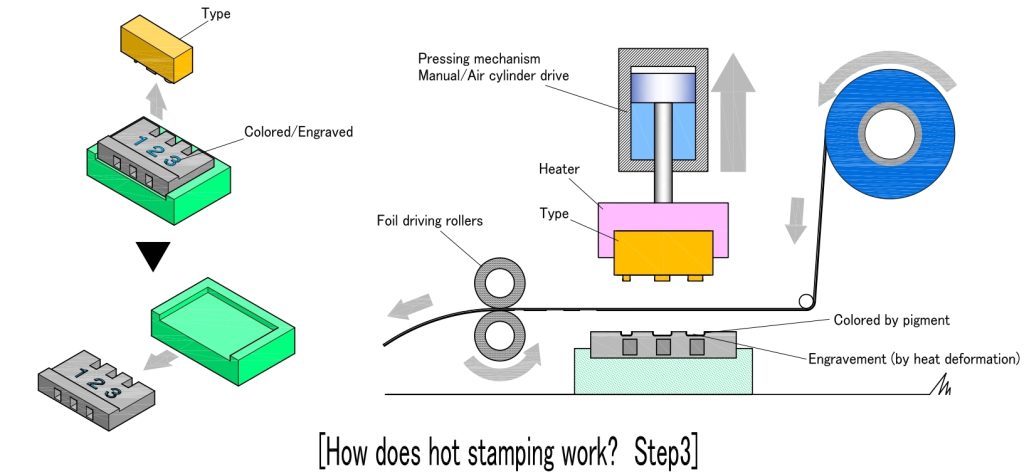

【Step3】Completion and Next Printing

Next, the type is released from the material either manually or by the lifting force of the air cylinder. Printing is considered complete when the material is finally removed from the jig.

When the type is raised, the marking foil is automatically moved forward by the foil-driving rollers so that its unused part located on the receiving holder is ready for the next round of printing.

Notably, the types need to be rearranged when changing the printing content. The methods for re-arranging types are as follows:

Rotating type

Rotate the type selection handle to adjust to the new print content.

Insert type

Set the rearranged types according to the type holder.

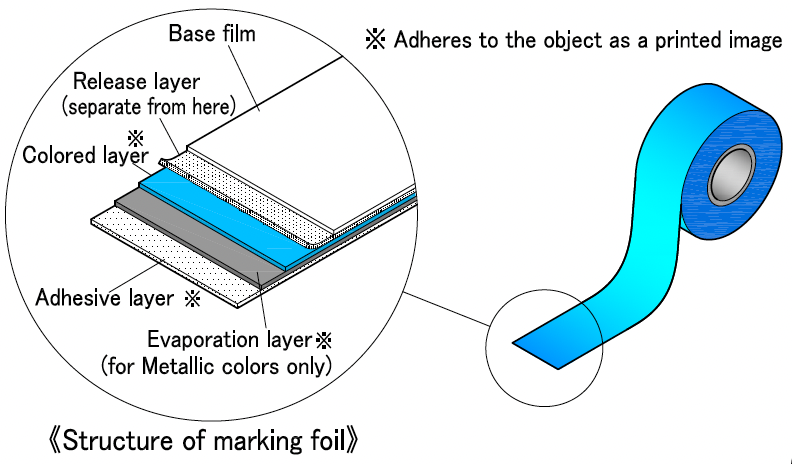

Structure of Hot Stamping Marking Foil

The marking foil for a hot stamping printer comprises the following 5 layers:

- 1. PET film: Film to hold each layer together.

- 2. Release film: The layer used to separate the top layer, the metalized layer, and the adhesive layer from the PET film.

- 3. Top layer: The protective layer that determines the color and pattern.

- 4. Evaporation layer: A metallized electroplated layer, which is also called an “aluminum layer” because it is composed of 90% aluminum.

- 5. Adhesive layer: Thermoplastic resin that adheres to the material.

While the print is separated by a release film, the layer below the top layer adheres to the material.

Comparison with Alternatives

vs. Inkjet Printing

Inkjet printers eject ink particles from a nozzle and then deflect these particles using an electrode to spray them onto the printing surface.

Unlike hot stamp printers, inkjet printing is non-contact and, therefore, it can print on material of various shapes, such as film, PET bottles, and cans for packaging.

However, some inkjet inks may contain organic solvents.

Additionally, small amounts of environmentally hazardous substances may be released from the ink during the drying process.

This does not occur in hot stamping machines. Hence, from this viewpoint, they may be considered eco-friendly.

Another advantage of hot stamping printers over inkjet ones is the former’s ease in changing color, since they do not involve cleaning ink tanks and nozzles. Instead, they simply require replacing the marking foil.

vs. Thermal Printing

Thermal head printers print by transferring ink onto the surface; hence, no engraving is made in this process.

Therefore, once the ink wears off, it becomes difficult to recognize what was printed.

Hot stamping printers, on the other hand, physically deform material into the shape of the print by engraving them, making it identifiable even when the pigment wears off.

Additionally, while a thermal head printer can be used only for flat surfaces, hot stamping printers can print on curved surfaces, such as electric wires.

This can be done by manufacturing typeface shapes that match curved surfaces.

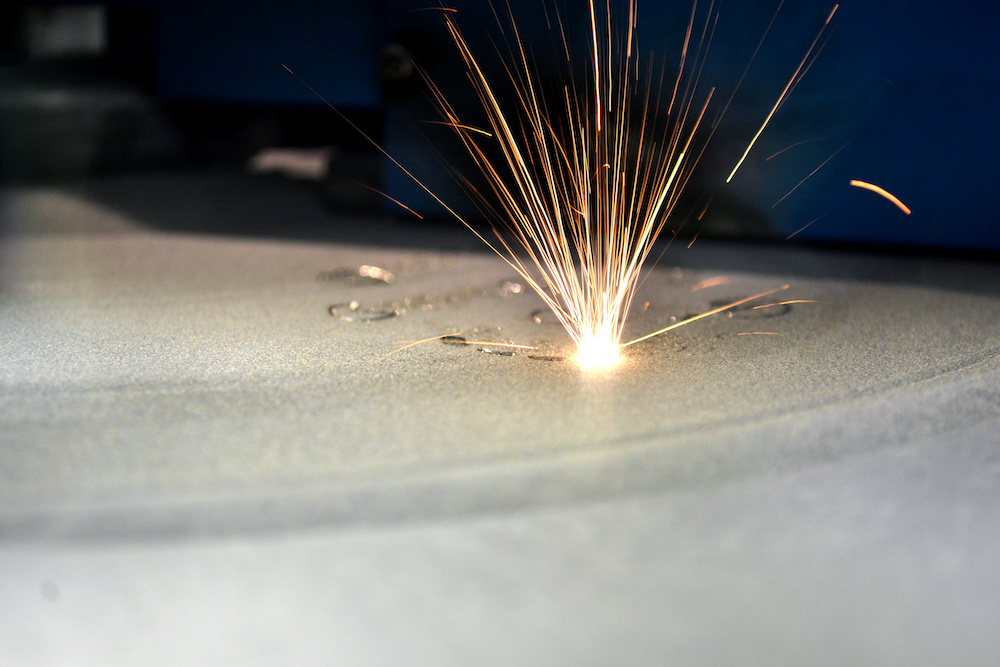

vs. Laser Printing

Laser printing machines use laser beams that are amplified by an oscillator and then irradiated onto the material to make prints.

Similar to inkjet printing, this too is a non-contact printing method.

Moreover, no ink foils are required in this process, thus lowering the cost of consumables.

However, some disadvantages of laser machines are that their installation costs are generally high, setting the focal length of a laser beam is a time-consuming process, the color of the laser print is limited only to oxidized colors of the material itself, and the combustion gases generated during the oxidation process create an environmental burden.

vs. Digital Printing

Digital heat transfer printing offers a more versatile and efficient alternative to hot stamping.

It allows for the reproduction of multi-color, high-quality images and supports a wider color range with the capability to reproduce over 10 million colors. This process is faster and enables immediate handling of the printed material post-printing.

In contrast, hot stamping is typically limited to single-color applications and requires more time for setup and processing. Digital printing's advanced capabilities, however, may come with different cost implications compared to traditional hot stamping.

vs. Silk Screen Printing

Silk screen printing involves pushing ink through a mesh screen to create a design on the surface of an object. It allows for multi-color designs and is highly versatile, suitable for a range of materials.

Hot stamping, on the other hand, uses heat and pressure to transfer pre-dried ink or foils onto a surface, typically resulting in a single color, shiny, and often metallic finish. It's commonly used for high-quality, durable marking on various products.

While hot stamping provides a unique texture and sheen, silk screen printing offers more flexibility in color and design complexity.

Benefits of Hot Stamping

Hot stamping printers have three major benefits, as described below.

Benefit 1: Long-lasting Print

Since the material is deformed and engraved in the shape of the typeface in hot stamping printers, the printing remains recognizable, even if the color peels off afterward because of the bumps and dents caused by the engraving.

Benefit 2: Color variety

The marking foils for hot stamping printers are available in a wide variety of colors.

In fact, metallic colors can also be used to create design-oriented identification printing.

Benefit 3: Operating cost

The major costs associated with hot stamping pertain to electricity and marking foils.

Therefore, the relatively inexpensive costs of marking foils and low power consumption with regard to hot stamping printers make them cost competitive against inkjet and laser printers, both of which use high-cost inks.

Limitations of Hot Stamping

Despite its many advantages, hot stamping printers also suffer from some limitations.

Limitation 1: Compatible Material

Some material and shapes may not be suitable for hot stamping printers, since the printer needs to make direct contact with the material.

In addition, printing can be done only in one color. Furthermore, multicolor photo-like printing is not possible through hot stamping.

Limitation 2: Thermal Resistant Material

The material to be printed upon must be heat-deformable, since hot stamp printing is performed by pressing a heated type against the material.

Moreover, when replacing the types, it takes some time to cool them down before installing new ones.

Limitation 3: The Number of Characters

Unlike inkjet and laser printers, there is a limitation to the number of characters that can be printed using hot stamping printers, since their types are a part of their mechanical structure.

Materials Suitable for Hot Stamping

While hot stamping printers can be used to print on a wide range of material, some exceptions do exist in the form of material that cannot be thermally deformed.

The following are examples of the suitability of certain material with regard to hot stamping printers:

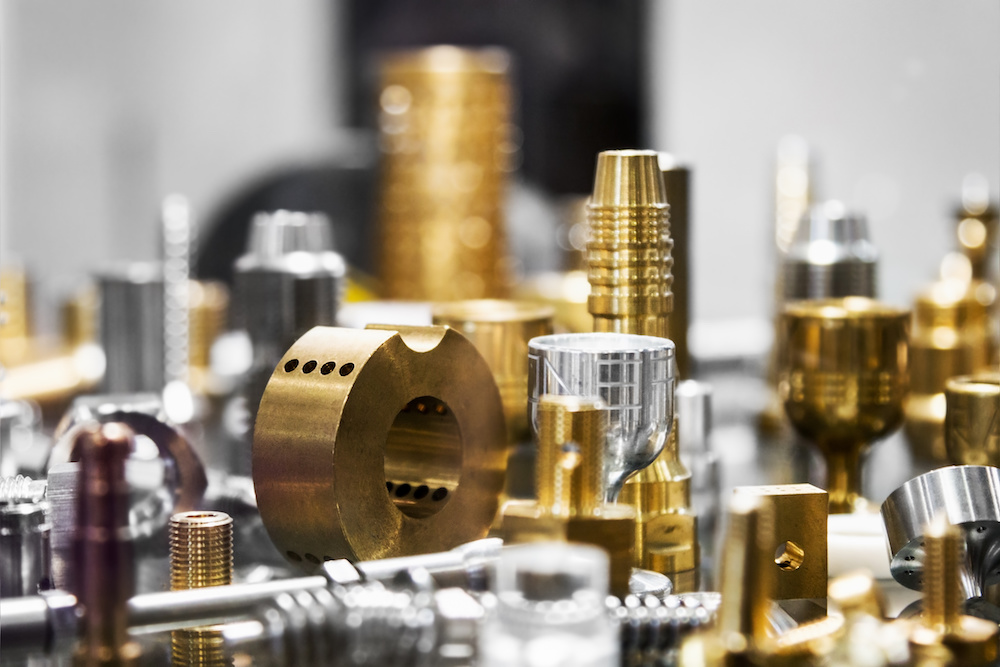

Plastic

Hot stamping printers can be used for printing on resins that can be deformed by heating.

These resin material range from general-purpose resins to engineering plastics.

As for thermosetting resins, they can become printable when heated above a certain temperature and on the application of appropriate pressure, even after they have hardened once already.

Ferrules

Hot stamping printers can be used for printing on wiring materials, such as tubing, coated wires, connectors, and cable ties, because they can be easily deformed by pressure and heating.

Heat Shrink Tubings

Hot stamping is an efficient method for marking heat shrink tubings, offering a combination of speed, flexibility, and quality. This technique is particularly effective for heat shrink tubings as it produces a smooth and professional finish, ideal for various applications ranging from automotive to medical use.

This process employs a die piece, known as "type" to press marking foil onto the tubing, resulting in durable and eye-catching designs. One of the standout features of hot stamping is its ability to easily switch print colors, and since it doesn't use liquid ink or organic solvents, there's no drying time required.

However, it's worth noting that hot stamping requires direct contact for marking, leading to intervals between each print, and changing the printed text involves physically rearranging the types.

Cable Ties

Marking on cable tie is indispensable for organizing cords and cables. Hot stamping stands out as a favored method for cable tie marking, delivering a neat and precise imprint on the material. This process employs a die piece, known as "type" to press marking foil onto the cable tie's surface.

When executed with the correct technique, hot stamping can deliver intricate designs that can endure harsh environments and daily wear. This method proves especially beneficial for marking on cable ties in industrial contexts, where monitoring equipment is vital for safety and efficiency.

Since metals are not thermally deformable, hot stamping printers are not suitable for them.

Therefore, we recommend using inkjet or laser marking printers for such purposes.

Other Materials

Hot stamping printers are suitable for use on textile material, such as leather, and on paper, since they can be easily deformed.

For these materials, printing solely by heating is quite possible (with no need to use marking foils).

Industries that Benefit from Hot Stamping

Hot stamping printers are used to print characters on wires, connectors, and ties to provide identification markings for electrical wirings.

In particular, they are in high demand when durability or design-oriented printing is required.

Aircrafts and Rockets

In the aerospace industry, identification printing is extremely crucial, since wrong wiring can lead to major accidents.

Although hot stamping printers have been used in this industry since the 1940s, their use on wire jackets for some equipment is now prohibited due to concerns that marking the wiring using direct pressure and heat may damage the wire jacket and cause short-circuits.

Nowadays, identification on cable ties and connectors are printed using laser printing, as well as not stamping technology.

Railway Cars and Equipment

In the railway cars and equipment manufacturing industry, where high-power (such as power systems) and low-power systems (such as control systems) coexist and a lot of wiring is required, hot stamping printers are widely used to implement identification markings.

Other Industries (Packaging, Bookmaking)

Metallic colors can also be used in hot stamping printers for design-oriented printing.

Notably, when printing on leather products, marking foils are not used. Instead, the types can be directly applied onto the surface to cause deformation.

Our Product Lineup

Our company offers a wide variety of hot stamping printers to serve the diverse printing needs of our customers.

Brief descriptions of our three hot stamping printers are provided below.

B200 Series

The Hotmarker B200 series is a versatile hot stamping printer that can be used for a wide range of material of various shapes and compositions.

Manufacturing a receiving holder that conforms to the material would make it possible to print on covered wires, control cables, connectors, and bundling bands.

Apart from this, custom-made printing types can be produced to print not only alphanumeric characters but also logos.

Metallic colors are also supported by this printer, thus enabling the printing of content characterized by a high level of design.

Two operation types can be selected in this printer: the Air cylinder type and the Manual type. This printer can also be integrated into a production line, making it an extremely versatile machine.

For more information, please refer to this brochure.

B200M-FC

The Hotmarker B200M-FC is a hot stamping printer that has been specifically made for mark tube production.

It comes equipped with automatic tube feeding and cutting functions that make it easy to print mark tubes that match the lengths of the characters to be printed.

The B200M-FC can print up to 8 digits and is compatible with mark tubes having an outside diameter ranging from 3.0 mm to 6.0 mm.

The small size of the B200M-FC (external dimensions of the main unit are 290 mm (W) x 290 mm (D) x 325 mm (H)) saves space and makes it portable.

For more information, please refer to this brochure.

M-3 series

The Hotmarker M-3 is a hand-held hot stamping machine that is ideal for identification purposes at on-site locations.

The M-3 can print directly on coated wires, as well as on mark tubes.

By replacing the character wheels and receiving holders, it can also be applicable for use in marker labels (to be attached to various things) and cable ties for bundling wires.

Furthermore, the characters of this printer can be changed easily by rotating the dial.

For more information, please refer to this Brochure.