Basics of Cable & Wire Identification | Professional’s Handbook

Table of Contents

ToggleWhy Does Cable Identification Matter?

Wirings are generally identified either by alphanumeric characters or by the color of the wires.

Proper identification of wirings is crucial to mitigating risks and improving efficiency, as explained below.

Risk 1: Prevention of Incorrect Wiring

The lack of proper identification may cause wires to be connected to the wrong positions.

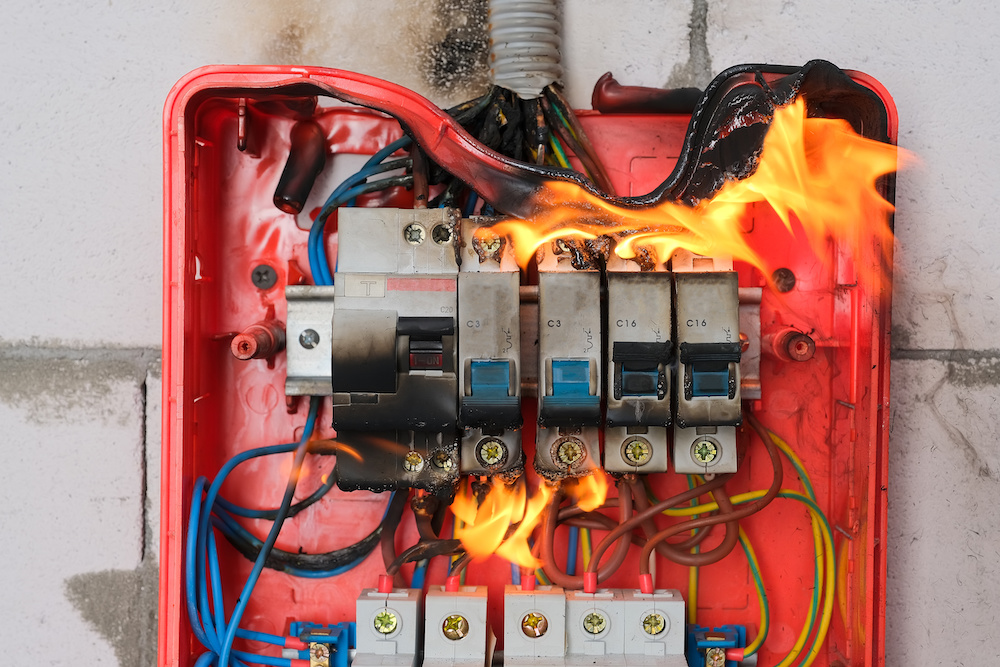

One such example could be when wiring meant to be connected to a 5 V circuit is mistakenly connected to a 230 V circuit. In the worst-case scenario, this may cause a fire or an explosion, ultimately leading to a fatal accident.

Another example is improper wiring in an operation indicator that incorrectly displays the “On/Off” functions.

Such a situation may injure the operator, who is very likely to misunderstand the operation status of the machine.

Therefore, wiring identification is extremely significant in preventing accidents, as discussed above.

Risk 2: Productivity Improvements

When conducting wiring work, proper identification not only improves the accuracy of the work, but also reduces work time, thus leading to higher productivity.

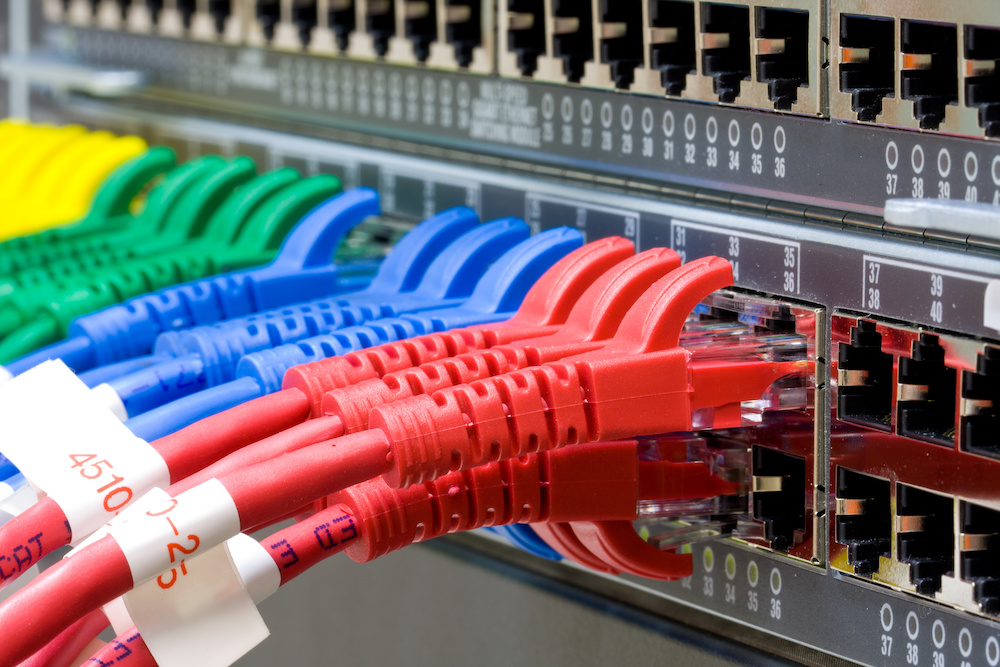

For example, when manufacturing a distribution panel, wiring work can be made easier by cutting each wire according to the specified lengths in advance, attaching a sleeve to them, and assembling them into a complete set of wiring with attached terminals.

While it may be possible to distinguish between wires without proper identification if the number of such wires is relatively small, it becomes an increasingly difficult task when the number of wires and connection points increase.

Risk 3: Increased Efficiency during Maintenance

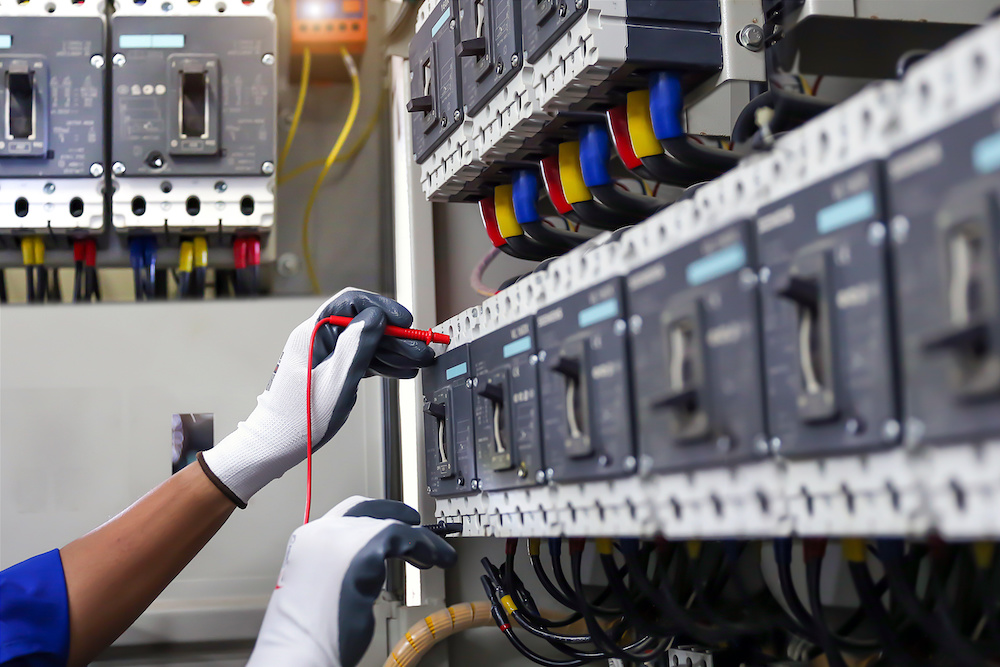

Wiring may sometimes be removed for periodic maintenance of control devices installed within switchboards and other equipment.

In such circumstances, without proper identification, it may take additional time to determine the specific wirings that need to be disconnected.

Ways to Identify Cables/Wires

The following four methods are widely used to identify wiring:

Method 1: Tags and Labels

The first method involves attaching tags or labels printed on a flat surface to the wires using a band or other means.

Alternatively, a sticker with handwritten characters may be pasted onto the connectors or wirings.

However, generally, the characters are printed directly onto the tags and labels.

Advantages

- ・Tags and labels can be attached to the wiring even after the terminals have been connected.

- ・If necessary, the tags and labels can be removed afterwards and replaced with new ones without changing the terminals.

- ・In cases where cable ties are used, this method of identification can be easily applied to bundled wirings.

Disadvantages

- ・When tags and labels are attached improperly, they may shift or peel off over time.

- ・Attaching tags and labels takes time and effort and thus may not be ideal from the productivity point of view.

- ・This method is not cost-competitive compared to directly printing on wires and using sleeves.

Method 2: Direct Printing (Handwriting)

This second method involves attaching handwritten identification to wiring films, tags, or connectors by a pen.

Advantages

- ・This handwritten identification will not fall off like a sticker.

- ・No special equipment is needed for printing purposes.

- ・The identification can be applied even after the wiring is complete.

- ・There is no limitation to the number of characters that can be written.

Disadvantages

- ・Depending on the type of pen used, the written characters may fade away with time.

- ・The handwriting may be difficult to decipher.

- ・Writing with a pen on thin wiring is a difficult task.

- ・It takes a lot of time and effort to add handwritings as identification markers to a high volume of wirings.

Method 3: Printing on Sleeves

Printing on sleeves is the most common identification method used for various types of wiring, including wirings that use crimp terminals.

In this method, a cylindrical sleeve-shaped resin piece, which is larger (in diameter) than the wiring, is printed upon using thermal transfer or other methods. The printed sleeve is also called the “marked tube”.

What is Thermal Transfer Printing?

Advantages

- ・The production cost of this method is lower than that of attaching tags and labels.

- ・When used in combination with crimped terminals, the crimped area can be insulated.

- ・Dedicated printing devices are available for mass production using this method.

Disadvantages

- ・Once the sleeve is fitted to the wiring, it is very difficult to make changes to the printing or replace it. Doing so would require removing the terminal.

- ・Since the sleeve size depends on the shape and size of the terminal and the wire being used (e.g., thickness of the terminal and wire), one sleeve size or one character size may not fit all.

- ・ Sleeves may come off upon detaching the wiring when it does not have a crimp (e.g. wiring that is inserted into a spring terminal block). However, using shrink tubing or flat-mark tubing can prevent such incidents.

- ・The sleeve needs to be inserted into the wiring before crimping.

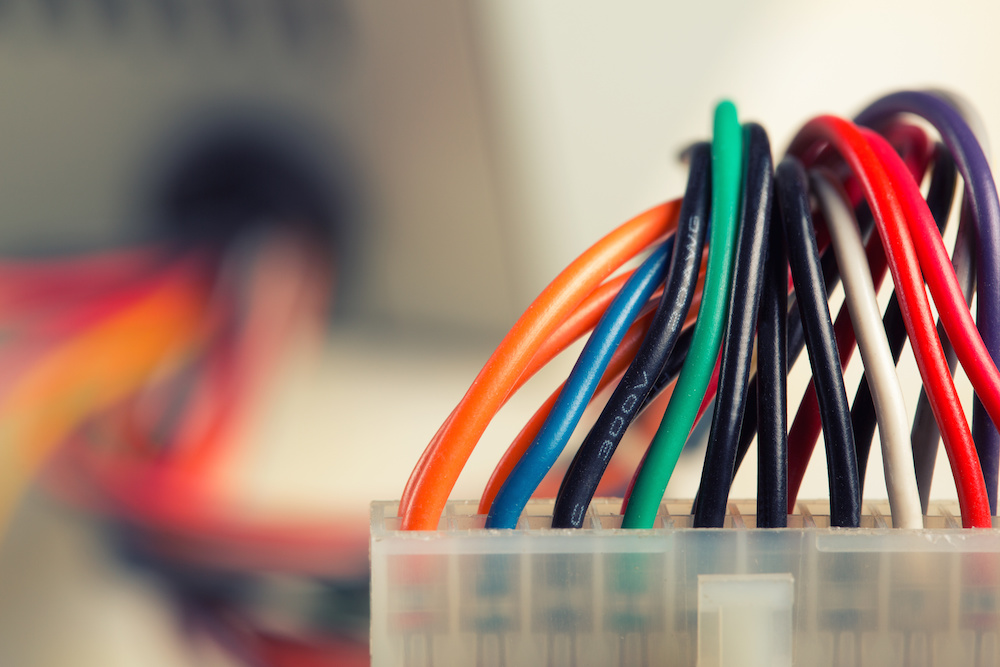

Method 4: Color Identification

The fourth method is identification based on the color of the wiring film.

Both single-color and double-color films are available for use. Apart from this, some suppliers make wiring films that use a combination of different colors.

Advantages

- ・Recognition based on the color of the wiring is easy.

- ・There is no specific need to attach labels/sleeves for identification.

Disadvantages

- ・Variation in the colors used is limited. Hence, it is not suitable for complicated wiring.

- ・There is a need to stock the inventory to match the number of colors used for the wiring.

Tips of Labeling Cables

This section provides some significant tips and cautions with regard to labeling cables.

Tip 1: Setting the Rules

We recommend determining the guidelines for a printing scheme in advance to prevent any complications in the printing process later.

Tip 2: Using a Label Printer

Using a label printer is recommended to avoid mistakes arising from handwriting. Handwritten letters can sometimes be difficult to recognize correctly.

Some examples of such instances are confusion in recognizing the number 1 from the number 7, and the number 0 (zero) from the letter O.

Tip 3: Using Minimum Characters

Consider limiting the length of the characters to be printed on the label and keeping them as short as possible.

This is because the fewer the characters on the label, the easier it is to recognize them. It also makes wiring diagrams easier to read.

Types of Marking Cables

The following section suggests a few tips and cautions that should be considered when attaching markers (tags) to cables.

Tip 1: Size and Shape

Always decide the rules to be followed regarding the size and the shape of the marker, depending on the use case, beforehand.

This will ensure that the wiring looks neater and make it easier to carry out maintenance activities.

Tip 2: Alignment

Markers must be attached correctly so that they are clearly visible. When inserting a marked tube into a crimping terminal, the orientation of the terminal and the marker should be properly aligned.

If the print on the marker is not visible, it may hinder maintenance and increase the time spent completing a work.

Tip 3: Prevention of Rubbing

If the markers are installed in such a way that they end up rubbing against each other—for example, when two terminals are tightly attached together—the markers may come off.

To prevent the marker from rubbing against another wire and ultimately coming off, use a single screw to fasten one terminal to another.

Types of Cable Tags

Product 1: Marker Labels

The Hotmarker SP series supports the automatic positioning and marking of labels.

In addition, these marker labels are durable and hard to peel off.

Apart from this, environmentally friendly PET labels and soft types that are convenient for wire wrapping are also available. Short pre-cut labels of fixed length and long labels that can be cut into desired lengths (4.0 mm to 10 mm) may also be considered for specific use cases.

Our marker plates have a mirror finish and are ideal for printing with Hotmarkers.

They are available from widths of 6.0 mm to 12 mm and have been deburred for safe use.

Our markers and vinyl tubes are compatible with wires ranging from 0.5 sq to 38 sq.

Moreover, these weather-resistant PVC tubes enable clear printing. These tubes are most suitable as wiring markers.

Our Cable Labeling Solutions

CTK’s Hotmarkers are industrial printing equipment that have a proven track record in printing for wiring identification in a variety of fields, including switchboards and control panels that are used to control equipment related to electric power, transportation infrastructure, industrial robots, and machine tools.

They are also widely used in the fields of automotive parts, consumer electronics, stationery, and decorative items. CTK’s Hotmarkers are reputed for ease of use of the equipment and the resistance of the print to fading.

Machine 1: Hot Stamping Printers

CTK offers two types of hot stamping Hotmarkers—the handy type and the stationary type. The handy type is easy to operate and favorable for use in on-site work.

Moreover, there are two variations of the types that can be used for printing—the rotary ring type and the insert type.

While characters can be easily selected in the rotary ring type, the insert type can be used for printing small characters and special typefaces.

Notably, the insert type is made of brass, which has higher thermal conductivity than steel, thus enabling consistent printing, even when used immediately after the type is changed.

Machine 2: Thermal Transfer Printers

Thermal printhead type Hotmarkers make fast and beautiful printing possible. The sensors and motors installed in the printing unit of this machine automatically transport the ink ribbon and tubes to prevent them from bending, thus ensuring consistent printing.

In addition, they offer a wide range of choices for selecting the desired cutting mode, such as cutting tubes into separate pieces or half-cutting them to keep the pieces connected on one side.

Moreover, this machine can set the number of half-cut pieces as well.