Thermal Transfer Printing 101 for Industry Professionals

Table of Contents

ToggleWhat is Thermal Transfer Printing?

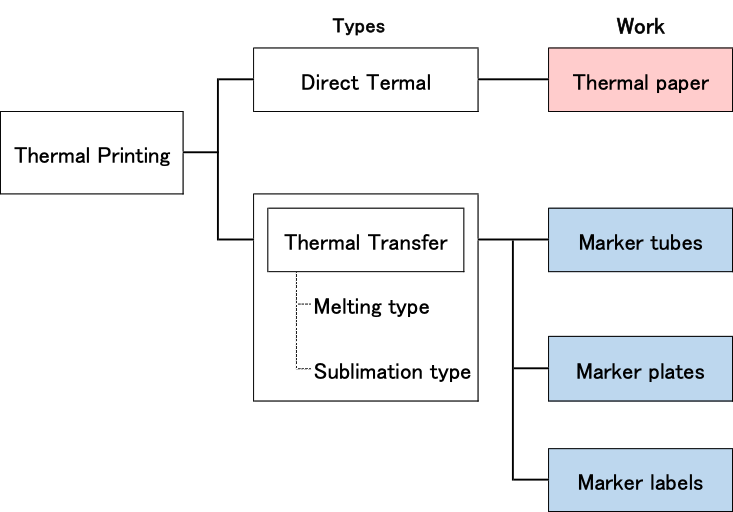

Thermal transfer printing is a printing method that involves using a heating element at the tip of a thermal printhead. It is used in a variety of applications, including product labels, bar codes, and receipts issued by supermarkets. Notably, there are two primary types of thermal printing—direct thermal and thermal transfer.

Direct thermal printing applies heat directly to the thermal paper, which then records the image.

Thermal transfer printing, on the other hand, heats the marking foil and transfers the image to the object.

Furthermore, there are two different types of thermal transfer printing—a melting type that uses the ink melt generated by heating and a sublimation type that turns the ink into gas by heating. Thermal transfer printing is also called “wax printing” or “image printing.”

Materials Suitable for Thermal Transfer Printing

Plastic

Thermal transfer printing can be used on plastic materials, such as packaging films and labels.

Packaging Films: Thermal transfer printing offers high-resolution graphics and texts on packaging films. This ensures that product details, barcodes, and other essential information are clear and durable, even under rough handling or adverse storage conditions.

Labels: Plastic labels printed using thermal transfer techniques are resistant to water, oil, and UV rays. This makes them ideal for products that may be exposed to harsh environmental conditions, ensuring that the printed information remains legible for extended periods.

CTK offers a line of printers for printing on plastic marker tubes, marker plates, and marker labels to identify wirings.

Heat Shrink Tubings

Thermal transfer printing, a method known for its versatility and efficiency, has become a preferred choice for marking heat shrink tubings used in industries like aerospace and telecommunications. This printing technique utilizes a heating element in a thermal printhead to transfer designs from a marking foil to the tubing.

The result is a sharp, vibrant, and durable print that can withstand harsh conditions without fading or smudging. While it offers precision even on the smallest details, it's essential to note that for certain applications, especially those involving bulky or uneven surfaces, alternative methods like hot stamping might be more suitable.

Materials Not Ideal for Thermal Transfer Printing

Fabrics

Thermal transfer printers excel at printing on flat, smooth materials like paper and resin. However, they face challenges when it comes to rough-textured fabrics.

The thermal printheads, which make direct contact with the material during the printing process, can find fiber materials challenging due to their coarse nature. Specifically, the texture of these fibers is often rougher than the individual heating elements on the printhead.

As a result, there's inadequate adherence between the printhead and the fabric, making the transfer process ineffective on such surfaces. For printing on textiles with this kind of texture, the hot stamping method proves to be a more suitable technique.

Cable Ties

Thermal transfer printing technology faces challenges when used for marking cable ties.

The uneven and often narrow surface of cable ties makes it difficult to ensure consistent contact with the printing heads of thermal printers.

Additionally, the high temperature of the thermal head can pose a risk of deforming the cable tie, especially if it's made of certain plastic materials that are sensitive to heat. As such, alternative marking methods, such as hot stamping printing are often preferred for cable ties to ensure legibility and product integrity

In inkjet printing, ink particles ejected from a nozzle are deflected by an electrode and sprayed onto the printing surface.

Unlike thermal printers, these printers can carry out printing without direct contact. Hence, they can be used to print on objects of all shapes and sizes, such as film, PET bottles, and cans for packaging.

However, thermal transfer printing is more environmentally friendly than inkjet printing because it uses inks containing organic solvents that release only a small amount of environmentally hazardous substances into the air when it dries.

Another reason why thermal transfer printing is more advantageous than inkjet printers is that the latter requires the cleaning of ink tanks and nozzles after each color change, while color changes in the former can be easily achieved by simply replacing the marking foil.

vs. Hot Stamping

Hot stamping pinting, in which the type is pressed directly onto the substrate, enables simultaneous printing and engraving, resulting in highly durable printing. However, in this case, the type needs to be replaced every time the printing content is changed.

In contrast, thermal transfer printing can be set up using keyboard inputs or through a PC. Hence, no time is expended on carrying out the preparations for printing.

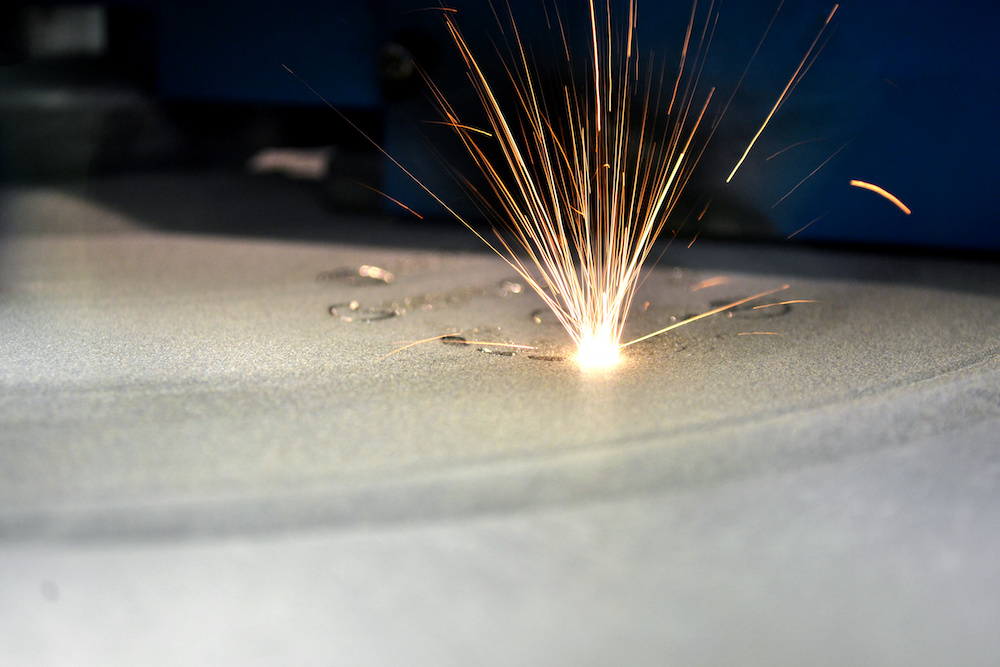

In the laser printing method, a laser beam amplified by an oscillator is irradiated onto the object, thus enabling non-contact printing similar to inkjet printing. In addition, since marking foils are not used in laser printing, the cost of consumables can be reduced.

On the other hand, laser printers suffer from disadvantages such as high installation costs, time-consuming focal length setting of the laser beam, the fact that only oxidized colors of the printing piece can be printed, and the environmental impact of combustion gas emissions during oxidation.

Durability of Thermal Transfer Print

The durability of thermal transfer print, especially its resistance to weather, is a critical consideration. One method to assess this durability is through weather resistance tests, which measure how long printed characters remain legible when subjected to elements like ultraviolet (UV) light and water sprays.

While it's possible to conduct this test by simply leaving the prints exposed to natural conditions, such a process could span several years. To expedite this, specialized machines are employed to simulate and accelerate the effects of weathering, enabling a quicker evaluation of the print's durability.

It's worth noting that all authentic CTK Hotmarker consumables undergo rigorous accelerated weathering tests based on the Japan Industrial Standards (JIS). This ensures that they consistently meet CTK's internal standards for durability.

Types of Thermal Printing

The advantages and disadvantages of direct thermal and thermal transfer printing are presented below.

Direct Thermal Printing

Direct thermal printing uses a thermal printhead that heats the thermal paper directly on contact.

Thermal paper is a special type of paper that develops color when heat is applied to its surface.

It is widely used by monochrome mobile label printers to print barcodes/prices of merchandise and by fax machines.

Advantages

Since thermal paper itself develops colors, ink is not necessary in direct thermal printing.

Effectively, this eliminates the need to purchase ink on a regular basis, thereby reducing running costs.

Disadvantages

Direct thermal printing can print only on thermal paper, which has low weather resistance (relative to other methods of printing), and its colors tend to fade over time.

This may limit the use of direct thermal printers for indoor and short-term labels and receipts.

Moreover, the printing colors are limited to black, dark blue, or sepia. Since thermal paper reacts to frictional heat, simply rubbing the paper ends up generating color on it.

Thermal Transfer Printing

Thermal transfer printing is conducted by applying a thermal printhead to a film-like marking foil for heating specific areas.

This activates the heated area of the marking foil, causing the ink to migrate to the object and adhere to it. The melting type thermal transfer printing prints by melting ink, while the sublimation type prints by turning the ink into gas.

Advantages

The advantages of thermal transfer printers over direct thermal printers include the availability of marking foils in a wider range of colors, the ability to print on non-thermal papers (e.g., general paper and resin), and more flexibility in terms of printable materials.

Furthermore, since they are more weather-resistant than direct thermal printers, they are more suitable for outdoor or long-term use cases.

Disadvantages

Thermal transfer printing uses consumables, such as marking foils, that needs to be purchased periodically.

Moreover, thermal transfer printers are bigger in size than direct thermal printers, since they involve the use of more components, such as the marking foil.

Types of Marking Foils

There are three types of marking foils used by thermal transfer printers: wax-based ribbons, resin-based ribbons, and wax-resin type.

While wax-based ribbons have a relatively low ink melting temperature, resin-based marking foils have a higher melting temperature (relative to wax-based type) and are more resistant to heat, abrasion, and chemicals. As a result, prints produced by the latter are more suitable for long-term storage purposes.

Meanwhile, wax-resin type inks possess the characteristics of both wax and resin types. Therefore, customers can select the ratio of wax to resin that best fits their desired application.

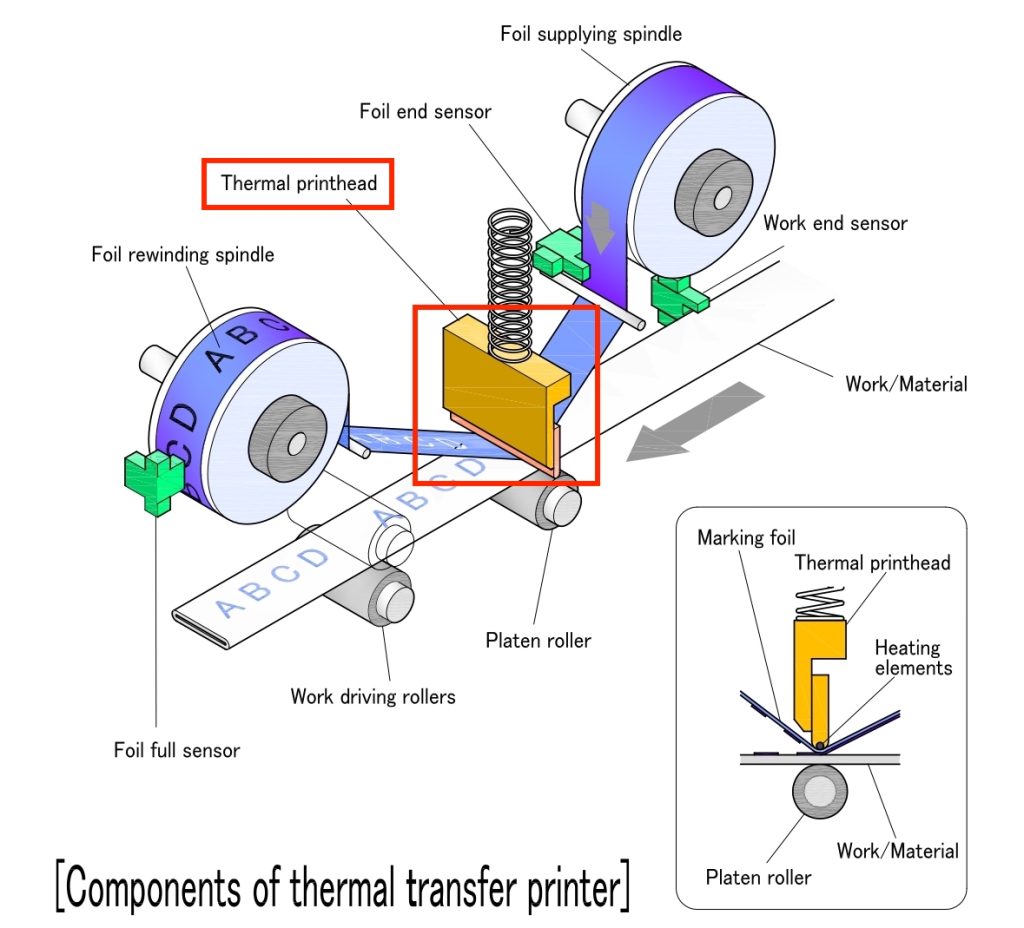

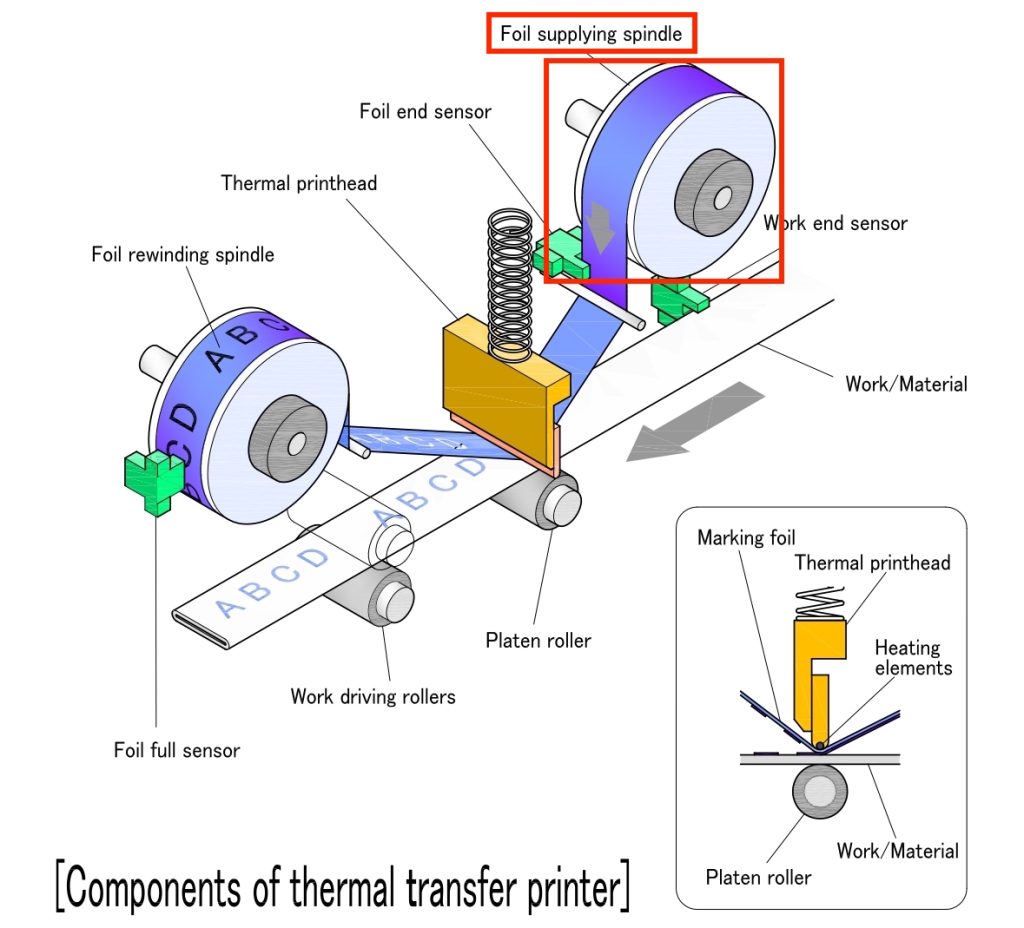

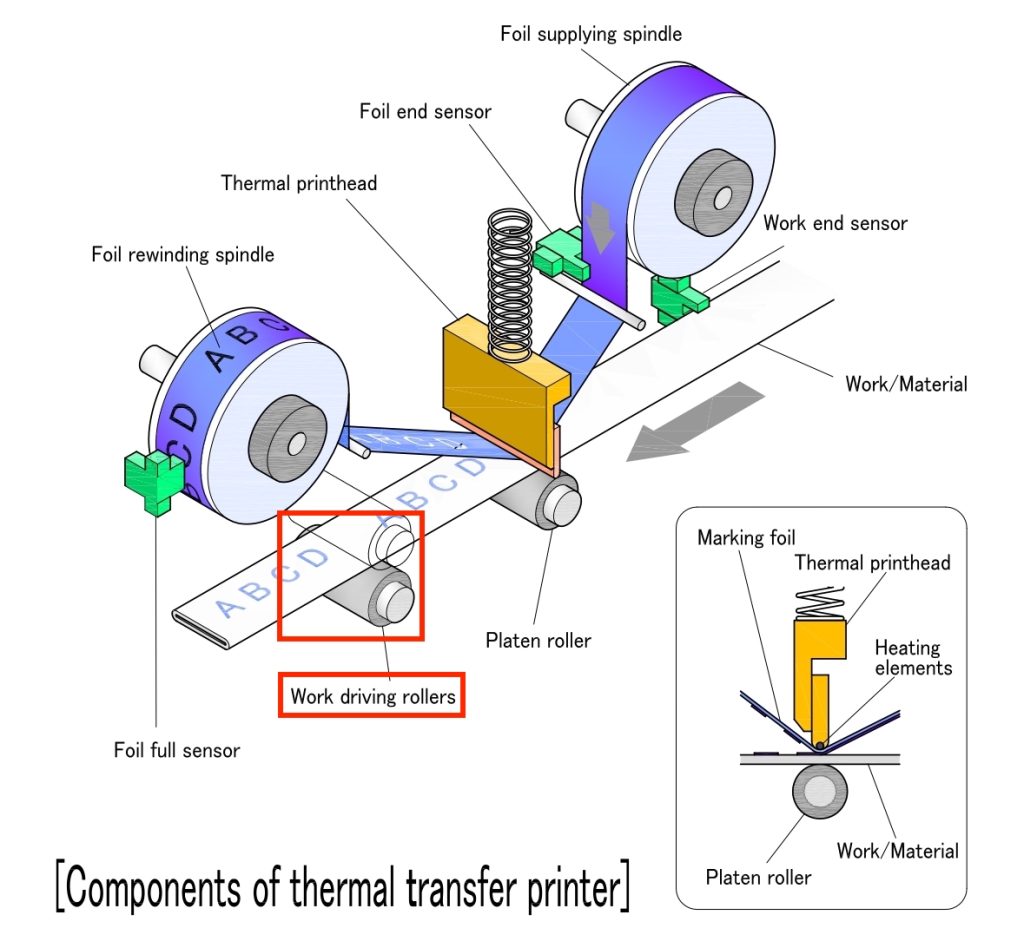

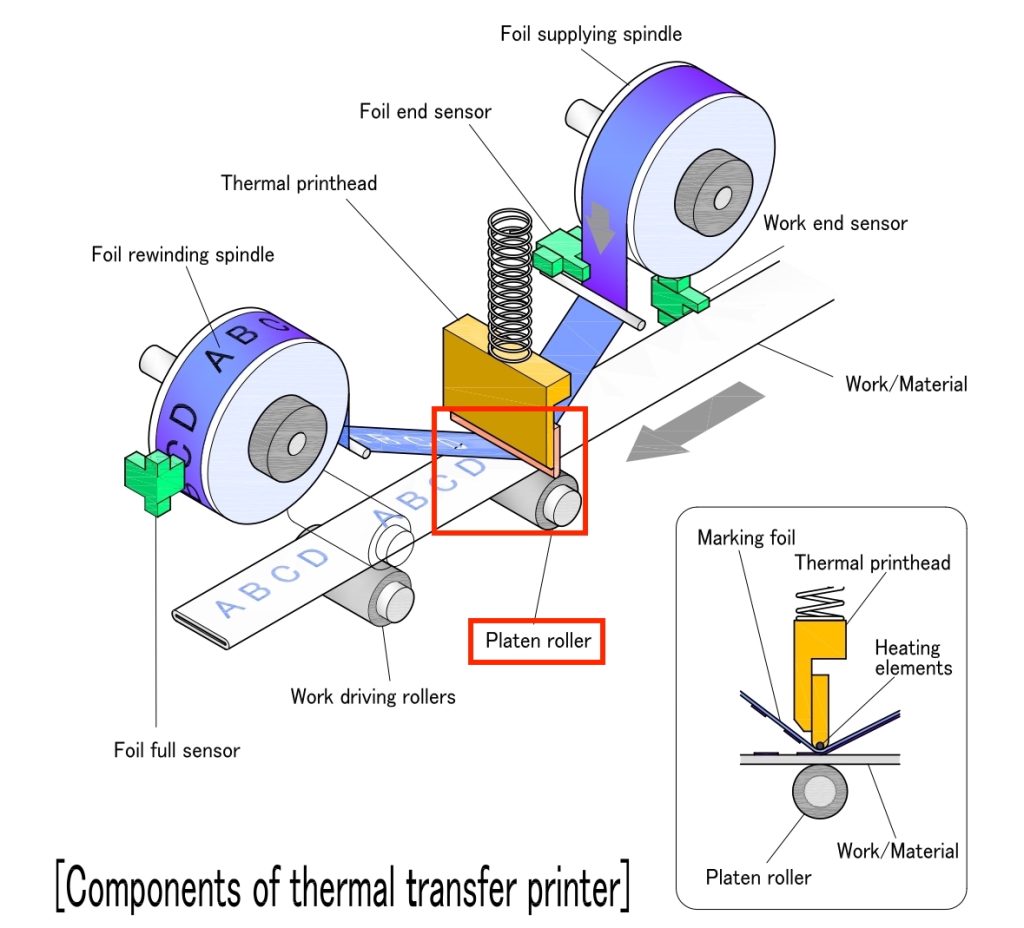

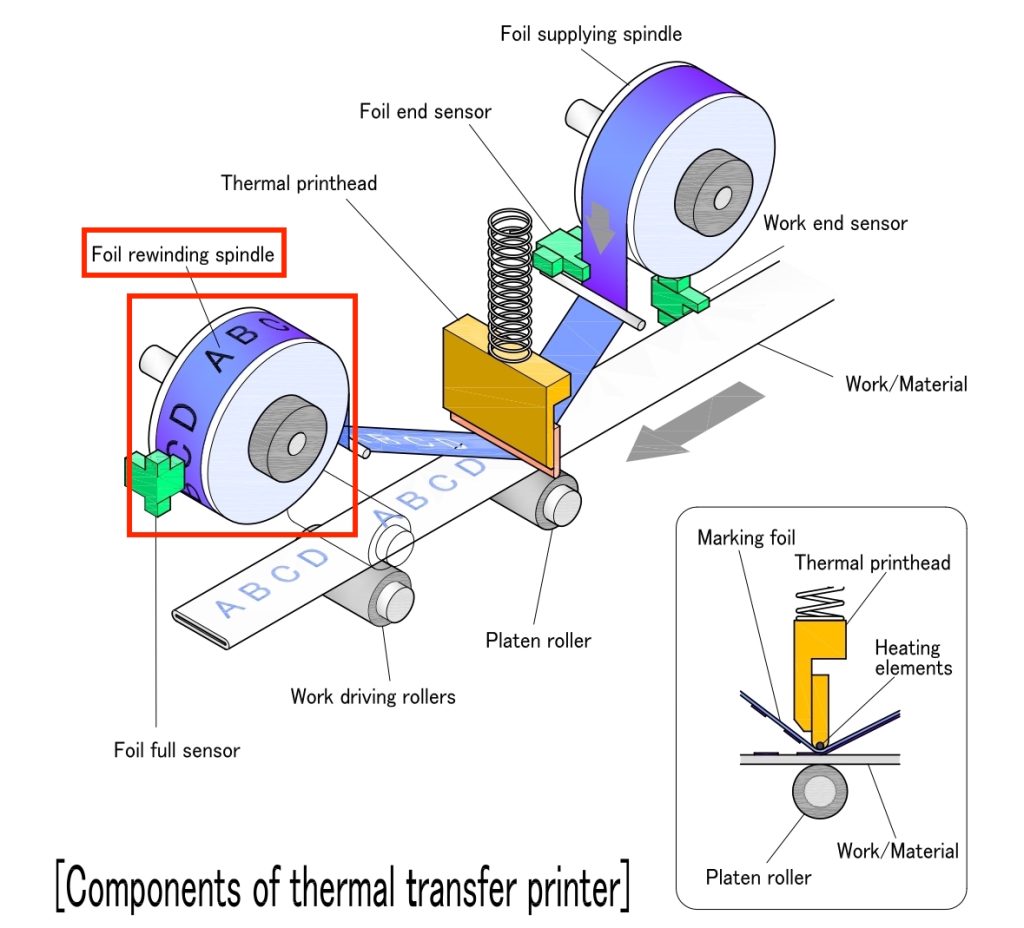

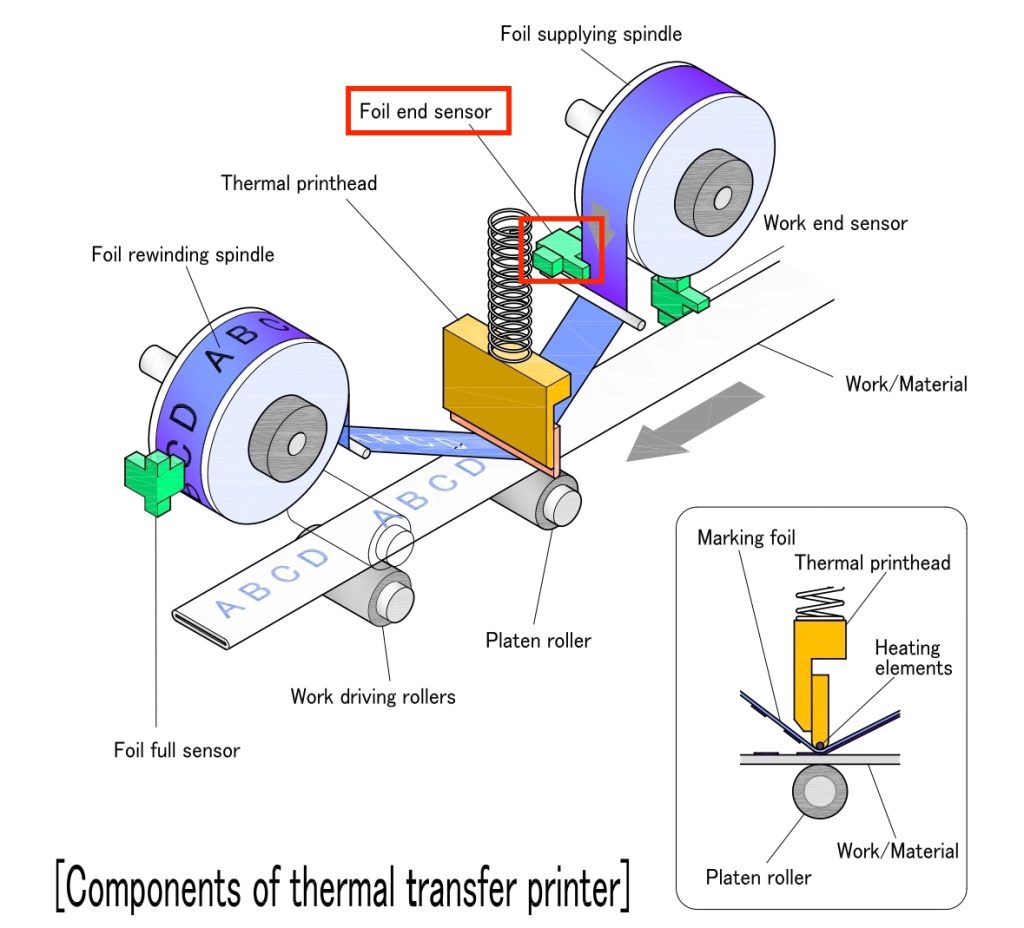

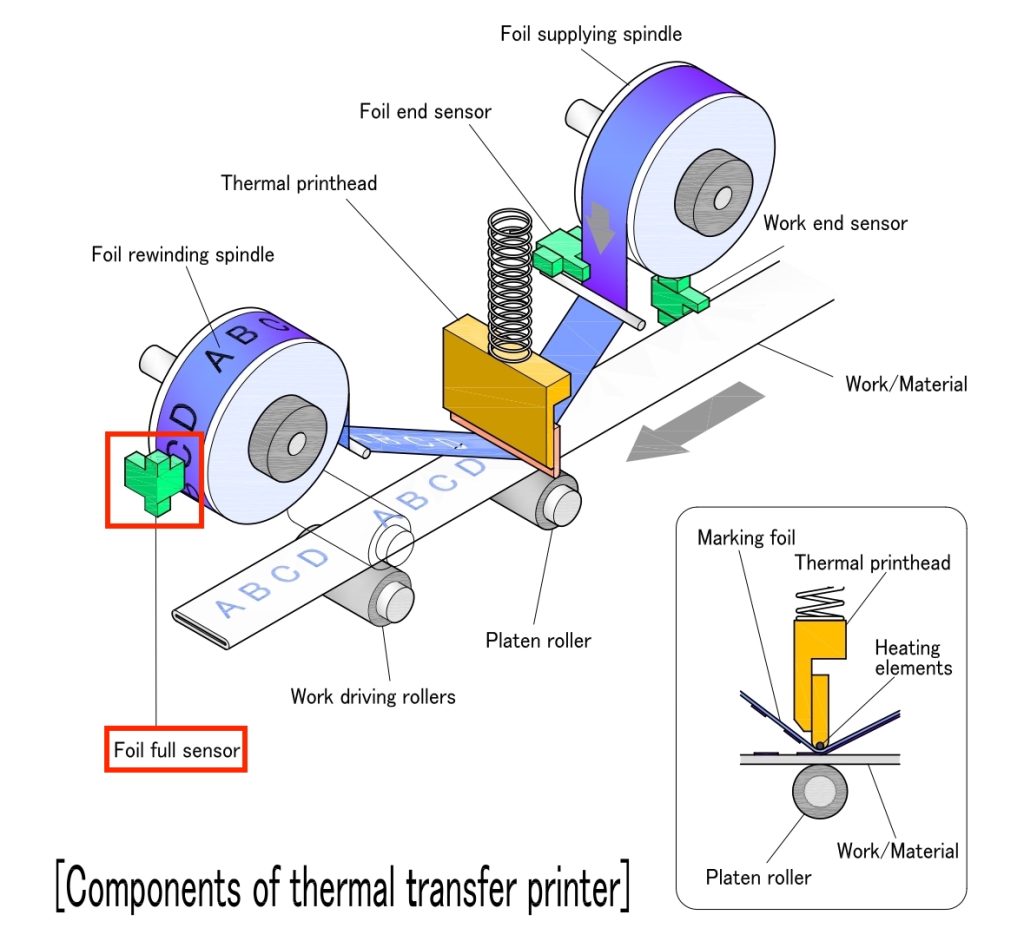

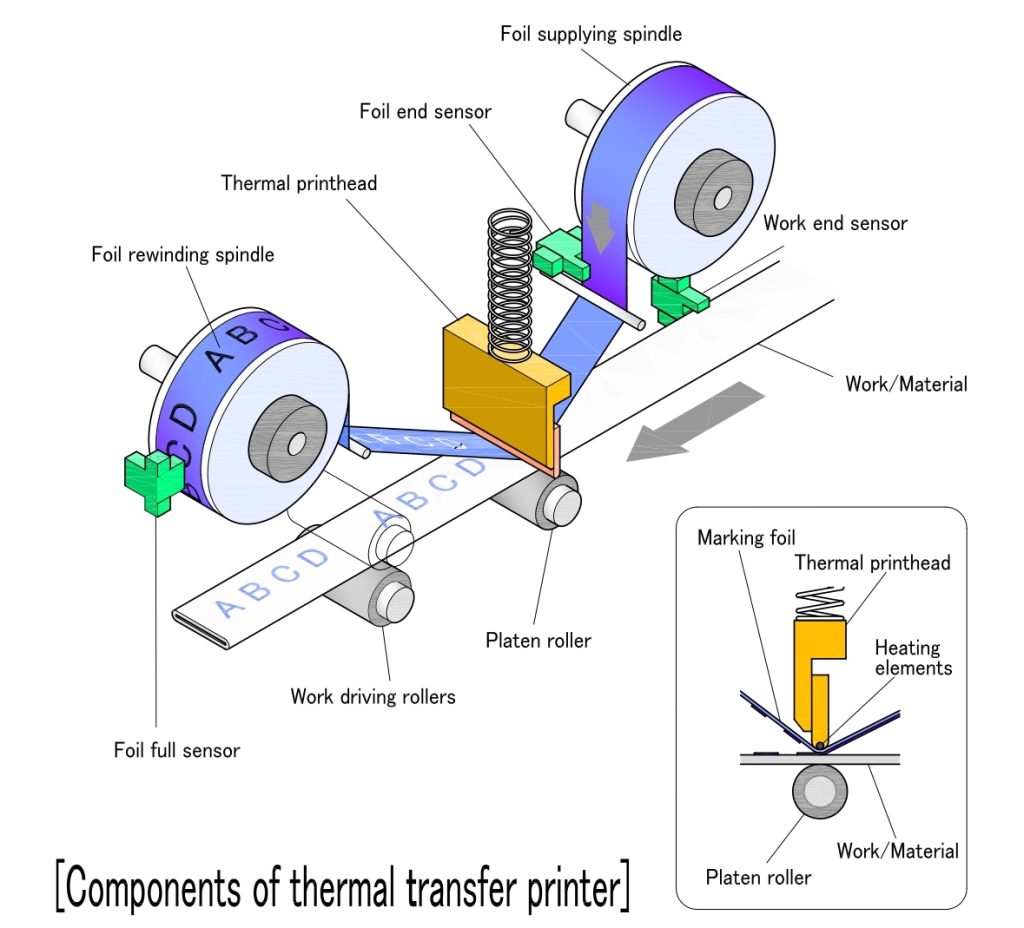

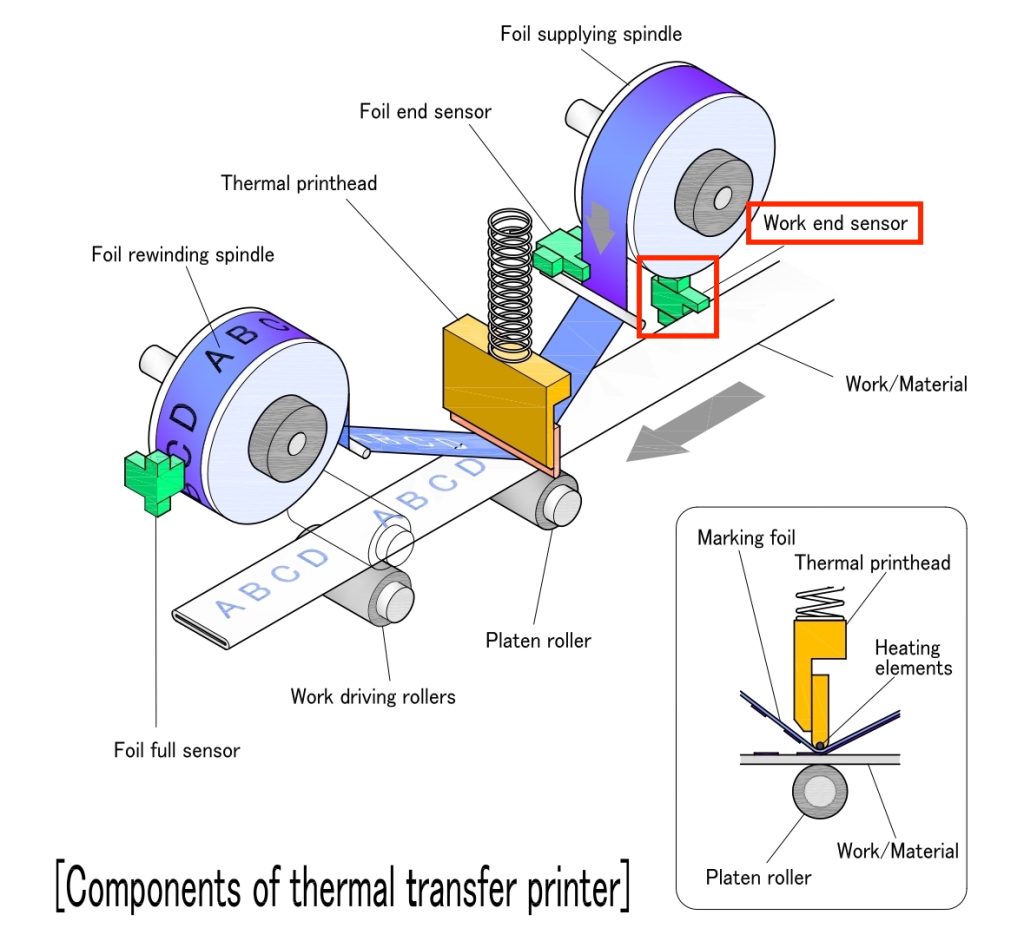

Components of Thermal Transfer Printers

The following are the main components of CTK’s thermal transfer printers.

Thermal Printhead

The thermal printhead is a key component that comprises a heat-generating element at its end, which heats the marking foil to transfer images onto the object.

The thermal printhead of CTK’s SP series is divided into three sections, where each section can be used one at a time.

Thus, when a phenomenon known as "dot loss" (i.e., when some part of the print is missing from the object) occurs after a printer has been used for a prolonged period of time, the user can switch to employing the unused section of the thermal printhead.

In this way, the usable life of the thermal printhead becomes three times longer than when the whole section is used at once.

While the design life of a thermal printhead under ideal conditions is about 10 km, our design prolongs it by three times (i.e., 30 km or 10 km x 3).

Foil Supplying Spindle

The foil supplying spindle is a reel that is used to set and feed the marking foil.

Therefore, this function ensures proper feeding of the marking foil.

Work Driving Rollers

Work driving rollers carry out the responsibility of transferring the object accurately so that it synchronizes with the marking time of the thermal printhead.

Platen Roller

The platen roller is a key component that supports the work situated below the thermal printhead.

It rotates and transfers the work forward after each round of printing. It should be noted that the platen roller tends to wear out after prolonged use, thus resulting in poor printing quality over time.

Therefore, it needs to be replaced periodically.

Foil Rewinding Spindle

Foil End Sensor

Work End Sensor

This sensor detects when the object has run out and needs to be replaced.

When it detects such a situation, it sends an error message and stops printing, similar to how a foil end sensor operates.

Foil Full Sensor

The foil full sensor detects when the foil rewinding spindle is completely filled with the used marking foil.

How to Choose a Thermal Transfer Printer

When choosing a thermal printer, the following key factors should be considered:

1. Processing capacity and production volume

Processing capacity is expressed in terms of the distance processed per second.

The processing capacity of CTK thermal printers is 27mm/sec (SP8600).

2. Total cost

In addition to the initial cost of purchasing the equipment, one should also consider that running costs will be incurred while operating the machine.

These costs include expenditures on consumables, such as marking foils, and replacement of components (such as spindles) that may occur when the machine remains in use for prolonged periods. Therefore, estimating the total cost must include both the initial cost and the running costs.

3. Shape of works

Product specifications vary depending on the type of work. CTK's SP series thermal printers can handle three types of work: marker tubes, marker labels, and marker plates (terminal nameplates).

Furthermore, the SP series printers can print on marker tubes with non-planar shapes by flattening the marker tube using the press roller that comes equipped with this series of printers.

Hotmarker, Next Level Thermal Transfer Printing Solution

CTK offers three models of mark tube printers that serve wiring identification purposes. While the SP8501 is the standard model, the SP8801 is a high-end model that can print materials with broader widths.

In addition, the latter is equipped with the function to cut a mark tube into pieces and then align and paste them onto a tape (the SP8501 and SP8801 are models primarily made for the Japan domestic market and, thus, are not CE compatible).