| Model |

SP8600 |

| Applications |

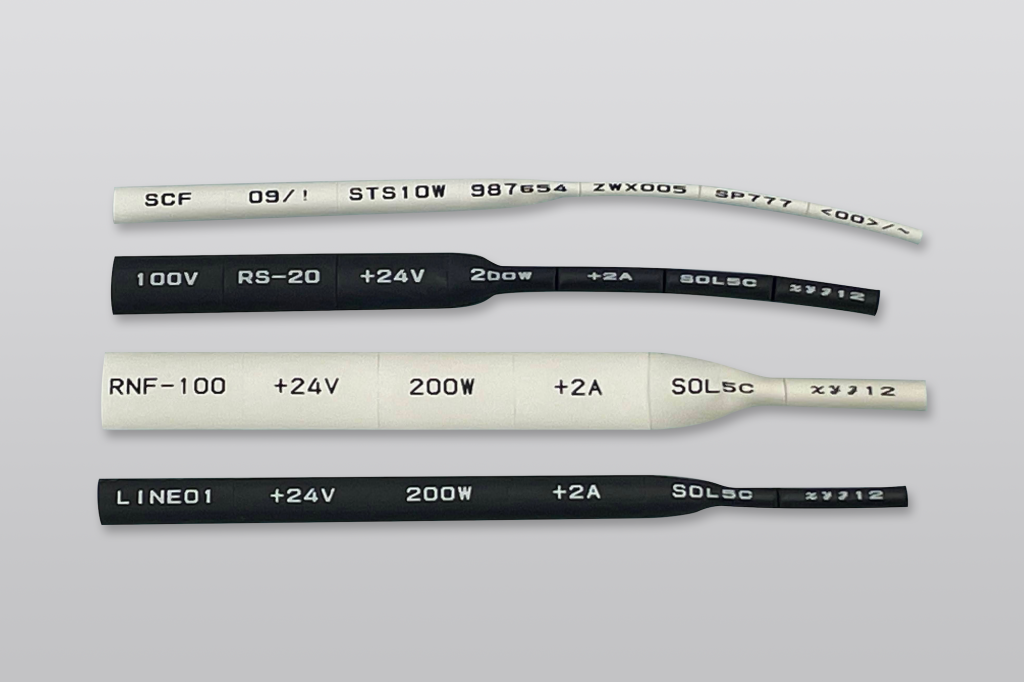

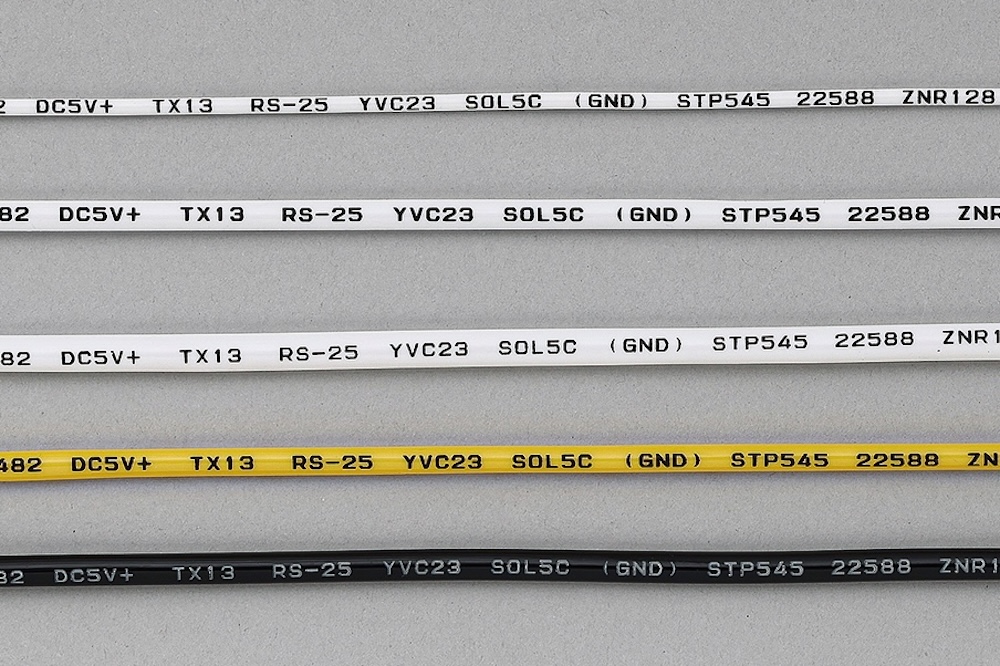

Tube |

Outer diameter |

φ2.0mm ~ φ28.0mm(CTK genuine tube) |

| Laid-flat width: |

Laid-flat width up to 45mm(approx.)(CTK Heat shrikable tube) |

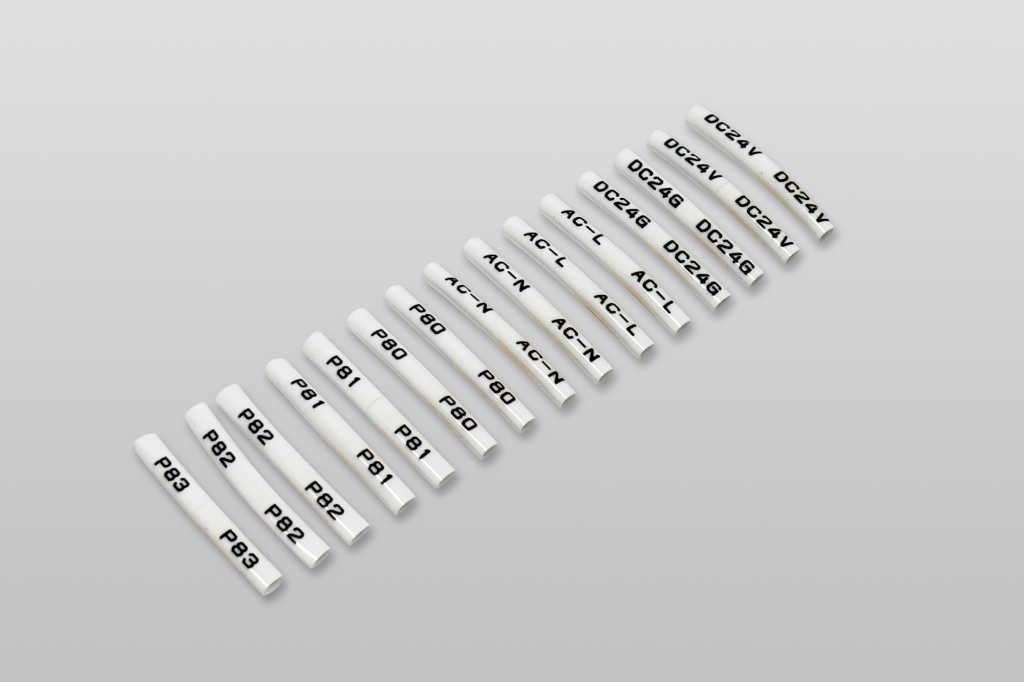

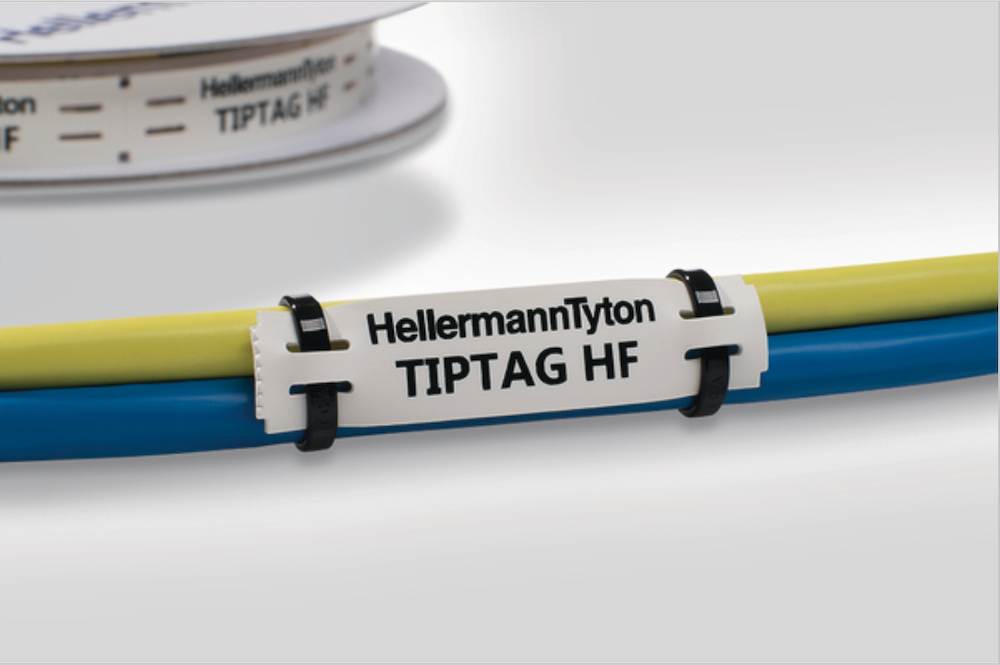

| Marker Labels (adhesive labels for device identifications) |

| Marker Plates (terminal ID boards) |

| Dimensions |

(W)432mm × (D)280mm × (H)302mm |

| Weight |

12.0kg |

| Printing method |

Thermal Transfer(300dpi or higher, horizontal direction) |

| Display |

LCD with white backlight(40 digits × 4 line) |

| Printing speed |

29mm~39mm/sec. Depending upon material type and cutting mode |

| Maximum printing length |

Tube : 200m, Tape : 200m |

| Maximum number of characters to input |

22,000 characters per file, up to 8 files can be stored. |

Max 1,000 line in main memory & Max 1,000

lines/bank × 8 banks in extended memory |

| Character size |

STANDARD FONTS |

2.4×2.4mm(HOR/VER) 1.8×1.8mm(HOR/VER) |

| 2.4×1.2mm(HOR/VER) 1.8×0.9mm(HOR/VER) |

| 3.0×2.4mm(HOR/VER) 2.0×1.2mm(HOR/VER) |

| 5.0×3.0mm(HOR/VER) 2.7×1.2mm(HOR/VER) |

| SPECIAL FONTS |

2.4×2.4mm(HOR) 3.0×2.4mm(HOR) |

|

| 4.0mm/5.0mm/5.5mm |

|

| Windows Fonts |

With a PC Connection, all the Windows Fonts availlable |

| Usable tape |

Width 20,30mm(CTK genuine tape) |

| Tube cutting method |

Auto half/full cut,No Cut |

| Internal memory |

Max 1,000 line x 8banks |

| External memory |

Max 1,000 lines/bank × 8 banks |

| Interface |

USB 2.0 full speed |

| POWER SUPPLY VOLTAGE |

Use only specified AC Adapter(110 – 240V) included in the package |

| Power consumption |

Max 150W |

| Operating environment |

10℃ – 30℃ |

| OPERATING HUMIDITY |

20 – 80%, non-condensing |

| CUTTING SPEED |

Maximum 1,633 mm/sec. |